Related Products

Pengukur aliran gas berbiaya rendah. Tidak perlu kompensasi suhu dan tekanan. Maksimal untuk ukuran sensor diameter DN2000. Tidak ada bagian yang bergerak dan p...

Vortex Flow meter digunakan untuk mengukur aliran cairan, gas, dan uap yang bersih. Hubungi kami untuk memilih jenis sensor aliran yang tepat dan dapatkan penaw...

Pengukur aliran turbin gas SGW, yang menggabungkan teknologi turbin canggih pengukur aliran digital untuk gas dari Tiongkok dan mancanegara dengan desain optimal, merupakan generasi baru pengukur aliran gas dengan presisi dan keandalan tinggi berdasarkan teori pneumatik, hidromekanika, elektromagnet, dll. Pengukur aliran gas turbin ini memiliki kinerja yang sangat baik pada tekanan rendah maupun tinggi, berbagai cara keluaran sinyal, dan sensitivitas rendah terhadap turbulensi fluida. Oleh karena itu, pengukur turbin gas banyak digunakan untuk pengukuran aliran gas, seperti: Pengukur aliran gas alam, pengukur aliran N2 ( pengukur aliran Nitrogen ), pengukur aliran biogas, pengukur aliran gas LPG, atau sensor aliran udara industri. SILVER AUTOMATION INSTRUMENTS adalah produsen pengukur aliran turbin gas terpercaya di Tiongkok .

|

Medium |

Clean gas with low to medium velocity,used such as biogas flow meter,LPG gas flow meter,nitrogen gas flow sensor. |

||||

|

Standard |

Gas measurement in closed pipe-Turbine flow sensor(GB/T18940-2003) |

||||

|

Gas flow meter Size & connection |

Flange type |

Stainless steel housing |

DN25-DN300 |

||

|

Aluminum housing |

DN25,50,80,100 |

||||

|

Carbon steel |

DN350,400 |

||||

|

Thread type |

Stainless steel(non compensation) |

DN25,40,50 |

|||

|

Stainless steel(compensation) |

DN25, 40, |

||||

|

Flange |

Standard |

GB/T9113.1-2000 |

|||

|

Others |

DIN,ANSI,JIS |

||||

|

Thread |

Standard |

BSPP(male) |

|||

|

Others |

BSPP(Female),NPT.,etc. |

||||

|

Accuracy & Repeatability |

Accuracy |

±1.5%R |

±1.0%R(Option) |

||

|

Repeatability |

≤0.5% |

≤0.15% |

|||

|

Turn down ratio |

30:1-10:1 |

||||

|

Gas meter Calibration |

Facility |

1. Master Meter calibrationfacility 2. Sonic nozzle gas flow calibrationfacility 3. Bell prover gas calibration facility |

|||

|

Environment |

Temperature: 20℃ |

||||

|

Relative Humidity: 75% |

|||||

|

Working Condition |

Medium temperature: -20 ~80℃ Atmospheric pressure: 86Kpa-106Kpa Environmenttemperature:-20 ~60℃ Relative Humidity5%-90% |

||||

|

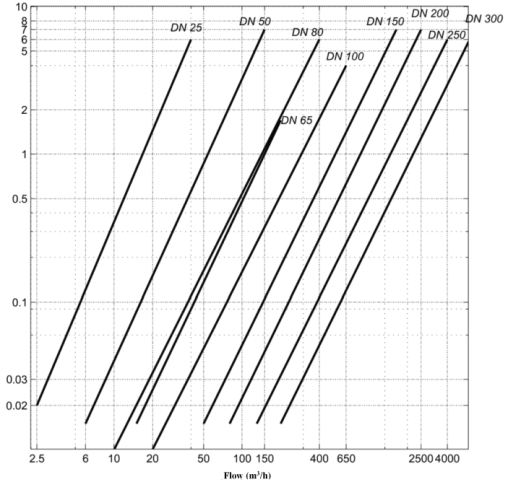

Typical Error Curve |

|

||||

Ukuran-Aliran-Laju Aliran

|

|

|

|

Standard Flow Range |

Extended Flow Range |

|

Size (mm) |

Standard (m3/h) |

Extended (m3/h) |

Standard Pressure |

Special Pressure |

||

|

DN20 |

S |

2-20 |

W |

4-40 |

1.6Mpa |

Thread≤4.0Mpa,Flange≤6.3Mpa |

|

DN25 |

S |

2.5-25 |

W |

4-40 |

Thread≤4.0Mpa,Flange≤6.3Mpa |

|

|

DN32 |

S |

4-40 |

W |

6-60 |

Thread≤4.0Mpa,Flange≤6.3Mpa |

|

|

DN40 |

S |

5-50 |

W |

6-60 |

Thread≤4.0Mpa,Flange≤6.3Mpa |

|

|

DN50 |

S1 |

6-65 |

W1 |

5-70 |

Thread≤4.0Mpa,Flange≤6.3Mpa |

|

|

S2 |

10-100 |

W2 |

8-100 |

|||

|

DN65 |

S |

15-200 |

W |

10-200 |

Flange≤6.3Mpa |

|

|

DN80 |

S1 |

13-250 |

W |

10-160 |

Flange≤6.3Mpa |

|

|

S2 |

20-400 |

|||||

|

DN100 |

S1 |

20-400 |

W |

13-250 |

Flange≤6.3Mpa |

|

|

S2 |

32-650 |

|||||

|

DN125 |

S |

25-700 |

W |

20-800 |

Flange≤6.3Mpa |

|

|

DN150 |

S1 |

32-650 |

W |

80-1600 |

Flange≤6.3Mpa |

|

|

S2 |

50-1000 |

|||||

|

DN200 |

S1 |

80-1600 |

W |

50-1000 |

Flange≤4.0Mpa |

|

|

S2 |

130-2500 |

|||||

|

DN250 |

S1 |

130-2500 |

W |

80-1600 |

Flange≤2.5Mpa |

|

|

S2 |

200-4000 |

|||||

|

DN300 |

S |

200-4000 |

W1 |

130-2500 |

Flange≤2.5Mpa |

|

|

W2 |

320-6500 |

|||||

|

DN350 |

S |

400-8000 |

W1 |

150-4500 |

-------- |

|

|

W2 |

300-9000 |

|||||

|

DN400 |

S |

500-10000 |

W1 |

300-9000 |

-------- |

|

|

W2 |

500-10000 |

|||||

|

Model |

SGW-N |

SGW-A |

SGW-B |

SGW-C |

SGW-D |

|

Picture |

|

|

|

||

|

Display |

No Digital Display No temperature and pressure compensation |

Digital Display Instant & Totalized Flow No temperature andpressure compensation |

Digital Display Instant & Totalized Flow Temperature and pressure compensation |

||

|

Diameter |

DN20-DN400 |

||||

|

Output |

Pulse |

4-20mA |

No |

4-20mA/Pulse |

4-20mA/Pulse |

|

Power |

24VDC±15% |

Battery*1 |

24VDC±15% |

24VDC±15% & Battery |

|

|

Flow Range |

Standard |

Standard or Extended Flow range |

|||

|

RS485 |

No |

RS485 Option |

|||

|

Power consumption< 0.5W |

|||||

|

Protection level: IP65 |

|||||

*1 Daya tahan baterai meteran aliran gas sekitar 56 bulan

| Item | Code | Description |

| General | SGW | Silver Gas turbine flow meter |

| Type | N | Without display, pulse output, 24VDC power supply |

| A | Without display ,4-20mA output, 24VDC power supply | |

| B | With display, Battery powered, without output | |

| C | With display,4-20mA output, 24VDC power supply | |

| C3 | With display, pulse output, 24VDC power supply | |

| C1 | With display, 4-20mA output,RS485,24V DC power supply | |

| D | Display, temperature and pressure compensation,4-20mA | |

| D1 | Display, T& P compensation,4-20mA,RS485 | |

| NominalDiameter | 20-400 | DN20-DN400 |

| Flow range | W(x) | Refer to table 2 |

| S(x) | Refer to table 2 | |

| Turbine Sensor Material | S | Stainless steel housing(DN25-DN300) |

| L | Aluminum housing(DN25,50,80,100) | |

| C | Carbon steel(DN350,DN400) | |

| Rotar, bearing Material | S | Corrosion Resistance ABS |

| L | Aluminium-Alloy | |

| Structure | N | Standard Structure |

| A | For Oxygen Only (O2 Only) | |

| Accuracy | 10 | ±1.0% of reading |

| 15 | ±1.5% of reading | |

| Explosion Proof | N | Non explosion proof |

| E | ExdIIBT6 | |

| Pressure Rating | N | Standard, (refer to table2) |

| H(x) | Customized,(refer to table2) | |

| Installation | FL | Flange connection |

| LW | Thread Connection *1 |

*1 Tentukan standar ulir meter turbin saat memesan, sambungan ulir tersedia pada meter aliran turbin DN20-DN50.

kami akan menghubungi Anda dalam waktu 24 jam.