Related Products

Tinjauan Umum Pengukur Level UltrasonikHL Pengukur level ultrasonik adalah sensor level cairan nonkontak untuk pengukuran level cairan dan padatan. Sensor ultra...

Transduser Tekanan Kapasitif Digital.Akurasi tinggi 0,1%, 0,2%.Dp, tekanan absolut, tekanan pengukur.Rentang: 0-20 Mpa (2900 PSI).

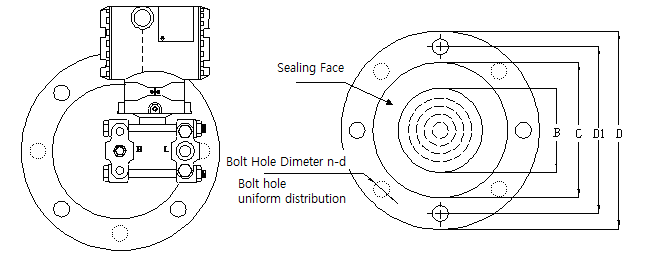

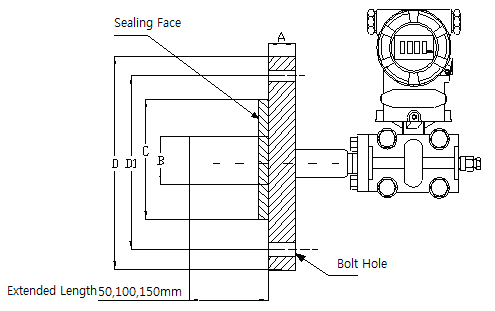

Pemancar level kapasitif tipe flensa tipe SHLT (pintar) dapat melakukan pengukuran level dan kepadatan yang akurat untuk semua jenis kontainer. Ini adalah semacam sensor tingkat tekanan. Flange flens dan flens diperpanjang tersedia, flensa 3 "atau 4", 1501b atau 3001b, pilihan flens yang dibuat khusus.

Spesifikasi Flange

|

No. |

Flange size |

Bolt Hole |

Rated Pressure Mpa |

||||||

|

Flange size |

OD D(mm) |

ID B(mm) |

Seal face C(mm) |

Thickness A(mm) |

No. n |

Diameter d(mm) |

Bolt Circle D1(mm) |

||

|

1 |

2”150LB |

152 |

48 |

92 |

18 |

4 |

19 |

121 |

2.5 |

|

2 |

2”300LB |

165 |

48 |

92 |

21 |

4 |

19 |

127 |

5 |

|

3 |

3”150LB |

190 |

66 |

127 |

22 |

4 |

19 |

152 |

2.5 |

|

4 |

3”300LB |

210 |

66 |

127 |

27 |

8 |

22 |

168 |

5 |

|

5 |

4”150LB |

229 |

89 |

157 |

30 |

8 |

19 |

190 |

2.5 |

|

6 |

4”300LB |

255 |

89 |

157 |

32 |

8 |

22 |

200 |

5 |

|

7 |

DN25(PN2.5/4.0) |

165 |

48 |

92 |

21 |

4 |

22 |

125 |

4 |

|

8 |

DN80(PN2.5/4.0) |

215 |

66 |

127 |

24 |

8 |

|

160 |

4 |

|

9 |

DN100(PN2.5/4.0) |

235 |

89 |

157 |

28 |

8 |

22 |

190 |

4 |

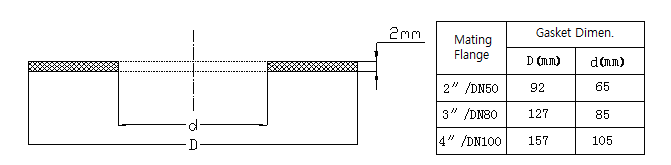

Dimensi gasket penyegelan flensa

Bahan penyegelan gasket flange dapat dipilih sesuai dengan media yang diukur, ada karet asbes, karet akrilonitril-butadiena, fluororubber, nilon, PTFE yang akan dipilih.

Pemilihan Model

|

A |

S |

Code (Single Flush Flange) |

Measuring range |

Code (Single Extended flange) |

Measuring range |

||

|

Analogue |

HART |

SHLT-3310 SHLT-4410 SHLT-4510 SHLT-4610 SHLT-4710 |

0-1.2-7.2kPa 0-6-36kPa 0-30-180kPa 0-160-1000kPa 0-400-2500kPa |

SHLT-3330 SHLT-4430 SHLT-4530 SHLT-4630 SHLT-4730 |

0-1.2-7.2kPa 0-6-36kPa 0-30-180kPa 0-160-1000kPa 0-400-2500kPa |

||

|

*Code |

Flange Specification |

Code |

Extended Length |

||||

|

A B C D E F G H I J |

3 ” 1501b 4 ” 1510b 3 ” 3001b 4 ” 3001b 2” 1501b 1” 1501b DN50 1.6Mpa/4Mpa DN100 1.6Mpa Special design |

A0 B1 C2 D3 |

0 mm 50 mm 100 mm 150 mm |

||||

|

Code |

Display |

||||||

|

M1 |

Linearity indicator 0-100% scale mark |

||||||

|

M2 |

Digital indicator |

||||||

|

|

Code |

Diaphragm material of high side flange |

|||||

|

|

K1 |

316L |

|||||

|

|

K2 |

Hastelloy C 276 |

|||||

|

|

K3 |

Tantalum (Only for flush flange) |

|||||

Komponen opsional

|

Code |

Mounting Bracket |

|

B1 |

Bend bracket for pipe mounting (2” pipe) |

|

B2 |

Bend bracket for plate mounting |

|

B3 |

Flat bracket for pipe mounting (2” pipe) |

|

Code |

Position of exhaust/vent valve |

|

D1 |

Side exhaust/vent valve of flange on top |

|

D2 |

Side exhaust/vent valve of flange at bottom |

|

Code |

Process Connection |

|

G0 |

NPT1/4 (F) |

|

G1 |

NPT 1/2(F) Waist type flange |

|

G2 |

NPT1/2-M20*1.5-Φ14 Welding pipe connector |

|

G6 |

M20*1.5(M) T-shape connector |

|

G7 |

M20*1.5(M) -Φ14 Welding pipe connector |

|

Code |

Process flange O-Ring material |

|

O1 |

Process flange O-Ring material: Nitrile rubber |

|

O2 |

Process flange O-Ring material: PTFE rubber |

|

Code |

Hazardous Area |

|

d |

Explosion separation type ExdsII BT5 |

|

i |

Intrinsically safe ExibII CT5 |

* Contoh Kode Pemilihan Flange:

Misalnya, 3 ", Flange 150LB dengan panjang diperpanjang 50mm, kode seleksi harus BB1

kami akan menghubungi Anda dalam waktu 24 jam.